The XNX Universal Transmitter is a flexible, universal gas detection solution compatible with Honeywell’s toxic, oxygen, and combustible gas sensing technologies, ensuring reliable monitoring in industrial environments․

Designed for versatility, it supports advanced communication protocols like HART, making it an essential component in modern gas detection systems for enhanced safety and operational efficiency․

1․1 Overview of the XNX Universal Transmitter

The XNX Universal Transmitter is a cutting-edge gas detection device designed for versatility and compatibility with Honeywell’s comprehensive range of gas sensing technologies, including toxic, oxygen, and combustible gas detectors․

Featuring advanced communication protocols such as HART, the XNX transmitter offers seamless integration into industrial safety systems, ensuring accurate and reliable gas monitoring; Its robust design and multi-functional capabilities make it ideal for hazardous environments, while its user-friendly interface simplifies configuration and operation․

With support for both digital and analog outputs, the XNX transmitter provides flexible connectivity options, catering to diverse industrial applications and enhancing overall system performance and safety standards․

1․2 Purpose of the Technical Manual

This technical manual serves as a comprehensive guide for installing, configuring, operating, and maintaining the XNX Universal Transmitter, ensuring optimal performance and safety in gas detection systems․

It provides detailed instructions for technicians and operators, covering calibration procedures, troubleshooting, and compliance with industry standards, while emphasizing safety precautions to prevent hazards during installation and operation․

The manual also outlines best practices for integrating the transmitter with compatible gas sensors and communication systems, ensuring seamless functionality in industrial environments․

Safety Information

The XNX Universal Transmitter requires adherence to safety standards, proper installation, and compliance with regulatory requirements to ensure safe operation and prevent potential hazards in industrial environments․

2․1 General Safety Precautions

Always read the manual thoroughly before installing or operating the XNX Universal Transmitter to ensure safe and proper use․ Follow all safety warnings and cautions to avoid potential hazards․ Ensure proper grounding and installation in accordance with local regulations to prevent electrical risks․ Avoid exposing the transmitter to extreme temperatures or corrosive environments․ Do not modify the device without authorization, as this may void certifications․ Use only approved sensors and accessories to maintain reliability․ Regularly inspect the system for damage or wear․ Adhere to calibration and maintenance schedules to ensure accurate gas detection․ Refer to the technical manual for detailed safety procedures and guidelines․

2․2 Compliance with Industry Standards

The XNX Universal Transmitter complies with FM and ATEX standards, ensuring safe operation in hazardous environments․ It supports HART communication protocols, enabling seamless integration with industrial control systems․ Compatible with catalytic bead, infrared, and electrochemical sensors, it provides versatile gas detection solutions․ This compliance ensures the device meets rigorous safety and performance criteria, enhancing its reliability, effectiveness, and durability in various industrial settings․ It is widely used in petrochemical, oil, and gas industries for detecting toxic and combustible gases, ensuring a safer and more controlled working environment․

Technical Specifications

The XNX Universal Transmitter supports HART communication and is compatible with Honeywell’s toxic, oxygen, and combustible gas sensors․ It operates on a 4-20mA output, ensuring reliable performance in hazardous environments․

3․1 Key Features and Capabilities

The XNX Universal Transmitter is an advanced solution designed for gas detection systems, offering compatibility with Honeywell’s toxic, oxygen, and combustible gas sensors․ It supports HART communication for seamless data transmission and integration with industrial control systems․ The transmitter features a 4-20mA analog output, ensuring reliable performance in hazardous environments․ With ATEX certification, it meets global safety standards for use in explosive atmospheres․ Its flexible configuration options and multi-sensor compatibility make it a versatile choice for industrial gas monitoring applications, enhancing safety and operational efficiency across various industries․

3․2 Compatibility with Gas Sensing Technologies

The XNX Universal Transmitter is fully compatible with Honeywell Analytics’ extensive range of gas sensing technologies, including catalytic bead, infrared, and electrochemical sensors․ This versatility ensures accurate detection of toxic, flammable, and oxygen gases in various industrial settings․ Its compatibility with HART communication enables seamless integration with existing systems, enhancing data transmission and diagnostics․ The transmitter supports multiple sensor types, making it adaptable to diverse gas detection requirements while maintaining high performance and reliability in hazardous environments․

Installation

The XNX Universal Transmitter installation involves mounting, wiring, and configuring the device according to the technical manual’s guidelines to ensure proper operation and safety in hazardous environments․

4․1 Pre-Installation Checks

Before installing the XNX Universal Transmitter, ensure the environment meets specified conditions, including temperature, humidity, and hazardous area classification․ Verify the power supply matches the transmitter’s requirements and that all necessary tools and accessories are available․ Check the sensor compatibility and ensure the transmitter is configured for the specific gas type․ Review the technical manual for torque specifications and wiring diagrams․ Perform a visual inspection for any damage or wear․ Confirm the communication protocol settings, such as HART, are correctly configured for integration with other systems; Ensure all safety precautions are followed to prevent accidental activation or damage during installation․

4․2 Mounting the Transmitter

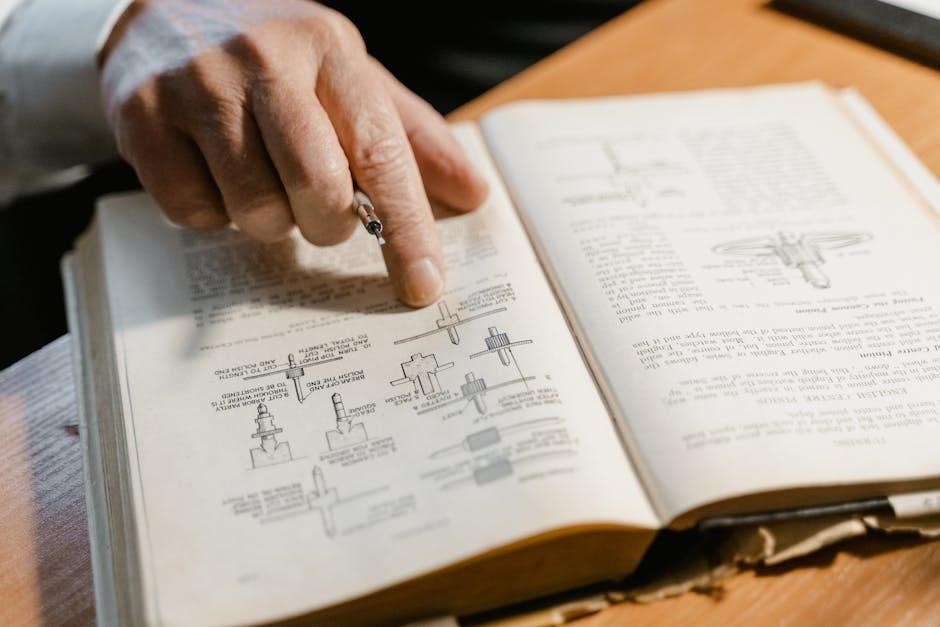

Mount the XNX Universal Transmitter in a location that ensures proper gas detection and accessibility for maintenance․ Ensure the transmitter is aligned correctly with the sensor and secured using the recommended mounting hardware․ Tighten all fasteners to the torque specifications provided in the technical manual․ Verify that the transmitter is level and properly oriented to avoid interference with gas flow or signal transmission․ Ensure all electrical connections are secure and comply with the system’s wiring requirements․ Refer to the manual for specific mounting configurations and compatibility with gas sensors․

Operation

The XNX Universal Transmitter operates seamlessly with HART communication, enabling precise gas detection and reliable performance across various industrial applications and gas sensing technologies․

5․1 Calibration Procedures

Calibration of the XNX Universal Transmitter involves precise zero and span adjustments to ensure accurate gas detection․ Using a HART communication tool, users can configure and verify settings․ The process includes applying known gas concentrations and adjusting the sensor response․ Regular calibration ensures optimal performance and compliance with safety standards․ Detailed step-by-step instructions are provided in the technical manual to guide technicians through the procedure effectively․ Proper calibration is critical for reliable operation in industrial gas detection applications․

5․2 Configuration Options

The XNX Universal Transmitter offers flexible configuration options to meet specific application requirements․ Users can customize settings such as gas types, measurement ranges, and alarm thresholds․ Advanced communication protocols like HART and Modbus enable seamless integration with control systems․ The transmitter also supports multiple sensor types, including catalytic bead and infrared technologies․ Configuration can be performed via the transmitter’s interface or through dedicated software tools, ensuring adaptability for various industrial environments and gas detection needs․

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance, including sensor cleaning and firmware updates․ Troubleshooting features like diagnostic codes and HART communication help identify and resolve issues efficiently․

6․1 Routine Maintenance

Regular maintenance is crucial for ensuring the XNX Universal Transmitter operates efficiently․ This includes checking and cleaning the sensor, verifying wiring connections, and updating firmware as needed․ Users should follow the manufacturer’s guidelines for calibration and diagnostic checks to maintain accuracy․ Additionally, inspecting the device for physical damage or environmental factors, such as dust or moisture, is recommended․ Routine maintenance ensures reliable performance, prevents downtime, and extends the lifespan of the transmitter․ Always refer to the technical manual for detailed procedures and compliance with safety standards․

6․2 Diagnostic and Troubleshooting Techniques

The XNX Universal Transmitter features advanced diagnostic tools to identify and resolve issues efficiently․ Utilize error codes and status indicators to pinpoint problems, such as sensor faults or communication errors․ HART communication enables detailed troubleshooting via handheld devices or software․ Regularly checking sensor integrity and ensuring proper installation can prevent common issues․ Refer to the technical manual for step-by-step troubleshooting guides and procedures to restore optimal functionality․ These tools help minimize downtime and ensure accurate gas detection performance in industrial settings․

Certifications and Approvals

The XNX Universal Transmitter holds FM approval and complies with industry safety standards, ensuring reliable operation in hazardous environments while meeting regulatory requirements․

7․1 Regulatory Compliance

The XNX Universal Transmitter meets regulatory requirements, including FM approval and ATEX certification, ensuring safe operation in hazardous environments․ It complies with industry standards for gas detection systems, adhering to strict guidelines for performance and reliability․ Designed to meet global regulations, the transmitter supports compliance with local and international safety standards․ Proper configuration and installation, as outlined in the technical manual, are essential to maintain compliance and ensure optimal functionality in various industrial settings․

7․2 Industry Certifications

The XNX Universal Transmitter holds industry certifications such as ATEX and FM approvals, ensuring its suitability for hazardous environments․ It is certified for use with Honeywell Analytics’ gas sensing technologies, including catalytic bead and infrared sensors․ These certifications validate its performance and reliability in industrial gas detection systems․ The transmitter also supports HART communication, enhancing its compatibility with modern industrial setups․ These certifications demonstrate its adherence to rigorous industry standards, making it a trusted solution for gas detection applications worldwide․

Accessories and Integration

The XNX Universal Transmitter is compatible with various accessories, including the DVC 100 series, OTV-122, and HALO, enhancing its functionality and integration capabilities in gas detection systems․

8․1 Compatible Accessories

The XNX Universal Transmitter supports a range of accessories, including DVC 100 series connection boxes, OTV-122, and HALO devices, ensuring seamless integration and enhanced functionality․

Additional compatible components include cables, junction boxes, and communication modules, which expand the transmitter’s capabilities and simplify installation across various industrial applications․

8․2 Integration with Other Systems

The XNX Universal Transmitter seamlessly integrates with Honeywell Analytics’ gas detection systems and third-party devices, ensuring comprehensive monitoring solutions․

Its compatibility with advanced communication protocols, such as HART, enables efficient data exchange and control within industrial automation frameworks․

By supporting multi-device networks, the XNX enhances system functionality, providing real-time data and improving operational safety across interconnected platforms․

References and Further Reading

For detailed instructions, refer to the official Honeywell website and the XNX Universal Transmitter Technical Manual․ Additional resources include product datasheets, user guides, and safety manuals․

9․1 Index of the Technical Manual

The index provides a comprehensive listing of topics, sections, and page numbers for easy navigation through the XNX Universal Transmitter Technical Manual․

It includes entries for installation, calibration, maintenance, troubleshooting, and compliance, ensuring users can quickly locate specific information and guidelines․

The index is alphabetically organized and cross-referenced to help users efficiently find detailed procedures and technical specifications․

Key terms such as “HART communication,” “gas sensing technologies,” and “safety precautions” are prominently featured for rapid access․

9․2 Additional Resources

For further understanding, additional resources include Honeywell’s official website, technical bulletins, and training materials․

These resources provide in-depth guides, safety protocols, and troubleshooting tips specific to the XNX Universal Transmitter․

Users can access PDF manuals, product overviews, and safety training presentations for enhanced knowledge․

Additional materials include wiring diagrams, compliance documentation, and FAQs for addressing common queries․

Visit Honeywell Analytics’ official documentation portal for the latest updates and detailed technical support․